The Price Behind The Pump

WHY GAS COSTS MORE IN CALIFORNIA — AND WHAT YOU'RE NOT BEING TOLD

Gas Tax Just Went Up

July 1 Gas Tax Increase: What You’re Really Paying For

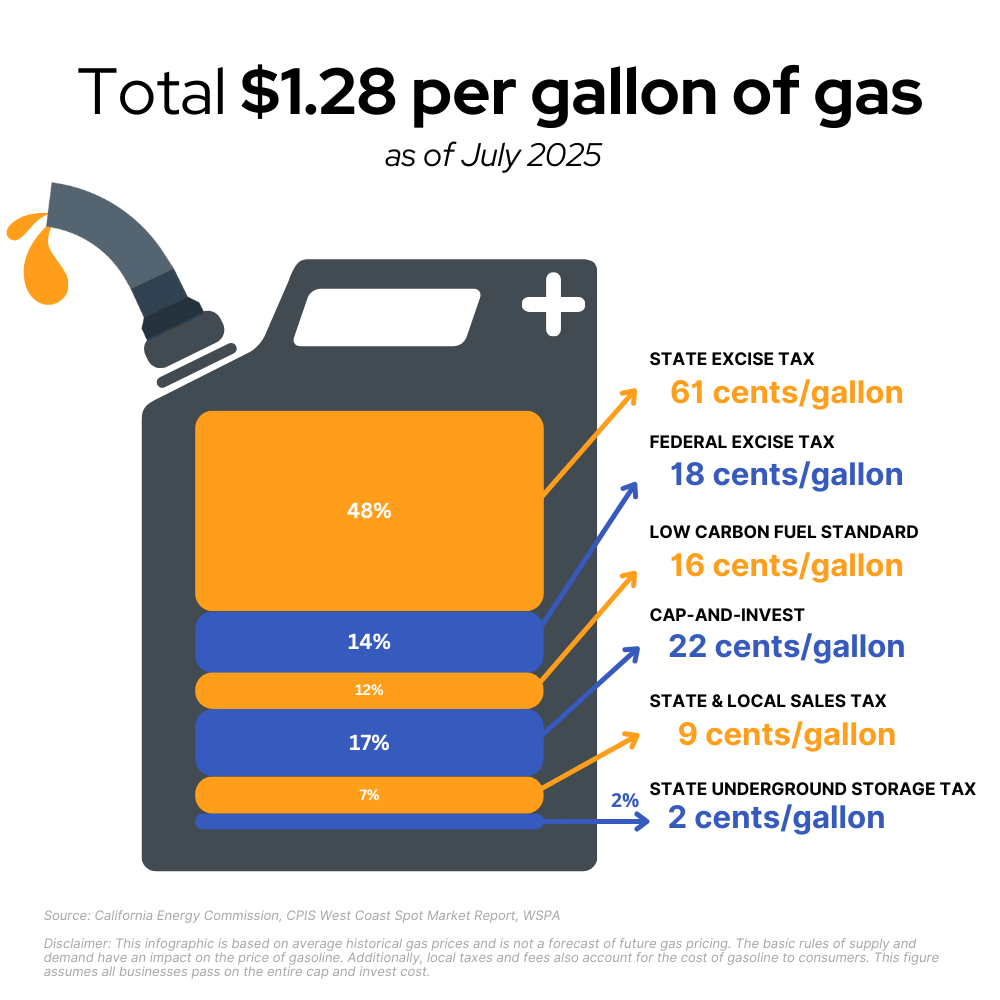

Starting July 1, California’s excise tax on gasoline increases to 61.2 cents per gallon, up from 59.6 cents — a direct result of the state’s annual inflation adjustment.

California regulators are also moving forward with a proposal that could add up to 65 cents more per gallon in the coming years, tied to changes in the Low Carbon Fuel Standard (LCFS).

These price increases aren’t about the global oil market — they’re about decisions made right here in Sacramento.

Learn more about the Low Carbon Fuel Standard and how it can affect you.

There are 3 main buckets that funnel into the price of gas in California:

THE LEGISLATURE HAD A CHOICE — AND TURNED IT DOWN

This year, several bills were introduced to stop these hikes or demand more transparency from the California Air Resources Board (CARB). CFCA supported all of them.

Unfortunately, the Legislature rejected every single one of these measures during this session — ignoring the real cost these decisions have on Californians.

Bills that would have stopped the LCFS-related price increases:

Bills that would have held CARB accountable:

The Low Carbon Fuel Standard (LCFS) is a program managed by the California Air Resources Board (CARB) that aims to reduce greenhouse gas emissions by requiring fuel providers to meet “carbon intensity” targets.

CARB is now proposing new, more stringent standards, and economists predict these changes could increase gas prices by up to 65 cents per gallon this year alone — all without a clear plan to protect working families or small businesses.

And these decisions are being made without direct legislative approval — meaning unelected regulators are driving up fuel costs without input from the public or their representatives.

The Advanced Clean Fleets (ACF) Regulation, adopted in April 2023, aims to phase out gas- and diesel-powered trucking fleets in California and replace them with zero tail pipe emission vehicles by 2042. Starting in 2026, trucking companies must gradually switch to electric trucks to help meet California's net-zero emissions goal by 2045.

Read the full study HERE

Gas stations and convenience stores employ approximately 193,000 people!

If you also count the fuel tank drivers and other jobs related to fueling our cars, it is closer to 200,000 Californians.

Did you know CA has over 12,000 convenience stores and close to 10,000 gas stations?

Almost 90% of those stations are owned and operated by independent owners, not big oil!

Learn more about the vital role the fuel industry plays in California's communities.

Did you know that California is the most heavily regulated state in the nation?

As a prime example, simply scroll through the entire list of regulatory agencies and departments that impose rules and regulations on the fuels industry in California:

That's 45 TOTAL agencies!

If you were wondering what some of the rules and regulations are, we've selected a few of the hundreds that our industry needs to manage every day so you can see for yourself the additional factors out of our control that add to the price of gas:

That's only 39 rules and regulations of the HUNDREDS that exist!

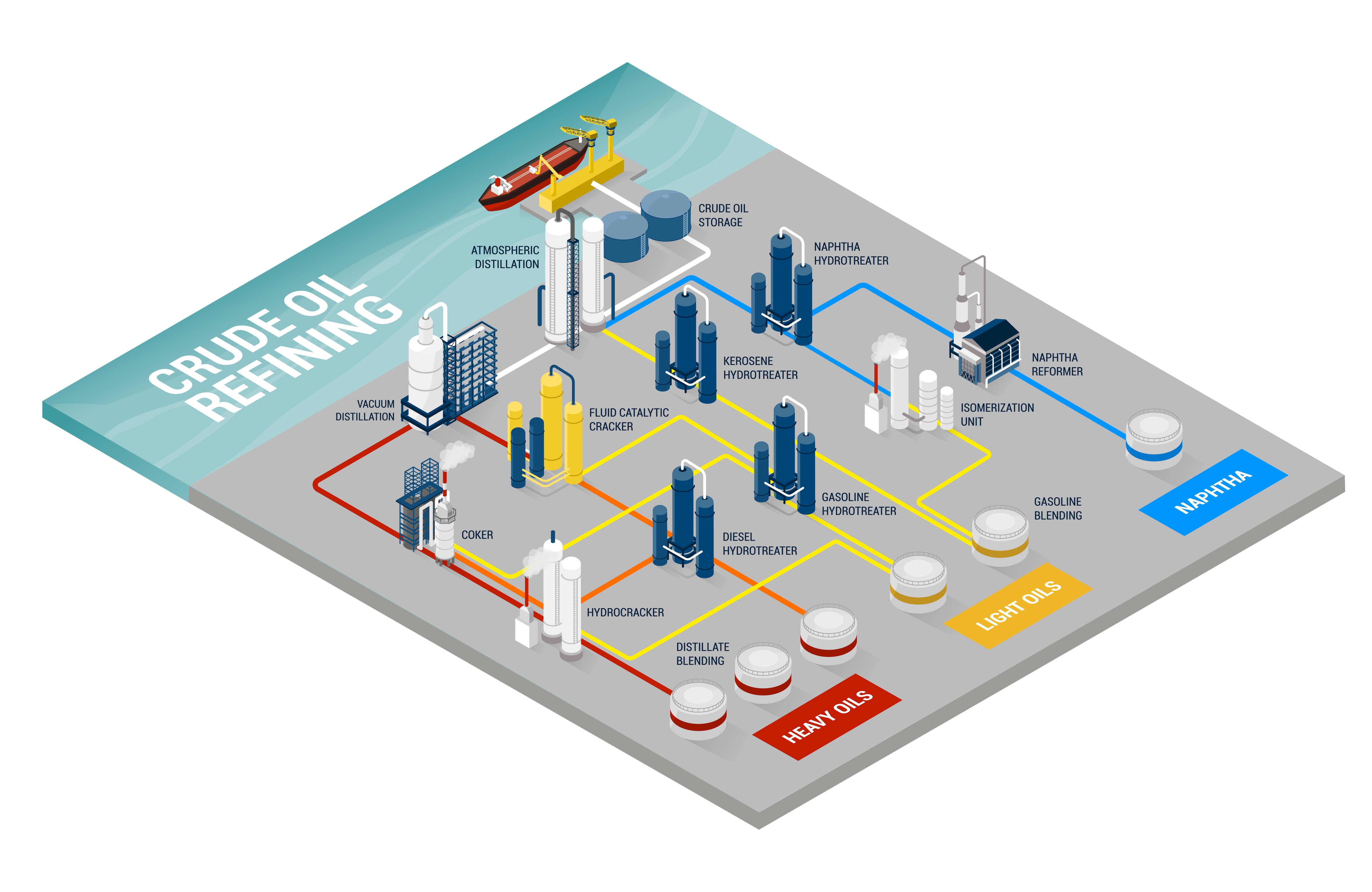

[Special thank you to Chevron El Segundo for this detailed explainer]

Chevron El Segundo is committed to producing the finest fuels through its refining process. Whether pumped through pipelines or shipped thousands of miles in tankers, crude oil arrives at our refinery in its rawest form.

It is the job of the people who work here to convert that crude oil into fuel we can use – gasoline for cars, jet fuel for airplanes, diesel for trucks and trains, propane and butane for home heating and barbecues, and fuel oils, coke, and certain chemicals for industrial use.

The refining process starts in the distillation towers.

Here, liquids and vapors are separated into components according to weight and boiling point. The lighter, more valuable fuels are separated from the heavier products.

From crude units, nearly all of the products are then treated to remove sulfur and nitrogen, primarily by "hydrotreating." Hydrotreating uses hydrogen to bind with sulfur and nitrogen.

The resulting sulfur is recovered and sold for industrial uses.

The nitrogen is converted to ammonia for sale to the fertilizer industry and for use in the refinery.

The remaining nitrogen is converted back to harmless nitrogen gas, which is a key component of the air we breathe.

The carbon dioxide we recover is sold for uses such as beverage carbonation. Only about 40 percent of crude oil is comprised of the ingredients for the high-quality fuels we produce. The remaining components of crude are heavy, poor-performing fuels.

To convert the heavy fuels to usable transportation fuels requires a relatively new process known as conversion or cracking.

Using cracking units, the large molecules in heavy fuels are converted into smaller molecules, which we can use to make the transportation fuels you need.

The Chevron El Segundo Refinery supplies 20 percent of all motor vehicle fuels and 40 percent of the jet fuel consumed in Southern California. In Order to make these products, we have three main types of cracking units:

Coker

The Coker is a thermal cracking unit. It heats the heaviest portion of the crude to a high temperature, causing it to crack into lighter materials.

The light materials produced are gasoline, jet fuel, and diesel.

The light fuel boils off, leaving behind a soild coal-like material called petroleum cake.

Petroleum coke is transported to the Port of Los Angeles, where it is shipped to Asia and Europe to be used in heating and manufacturing.

Fluidized Catalytic Cracking Unit

The Fluidized Catalytic Cracking Unit (FCC), or "cat cracker," cracks the heavy material into gasoline, the most demanded transportation fuel.

Hyrdocracking Unit

The Hyrdocracking Unit is another catalytic cracking unit. Chevron's patented hydrocracking process is called an ISOMAX Unit. The catalyst in the ISOMAX unit is designed to crack heavy material into jet fuel.

After the molecules have been cracked, these fuels are still not ready to power an automobile or jet engine. The molecules must be arranged and rearranged to burn cleanly and with better performance.

The Catalytic Reforming and Alkylation processes all result in higher octane fuels which are designed to meet these needs.

Finally, after more than 200 hydrocarbons and additives have been blended into the fuel, the finished products are held in storage tanks, ready to be shipped via tanker, truck, or pipeline to our customers.

Credit to Chevron: https://elsegundo.chevron.com/our-businesses/the-refining-process